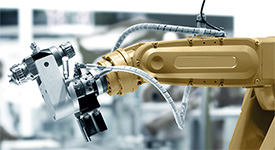

Since our inception in 1994, lmex has constantly evolved as a result of our attention to technological innovations. Now in the companies 4.0 era, lmex has upgraded to automated manufacturing with the help of state-of-the-art equipment. We use robots to do the casting, glazing and relocation of products. This improves safety conditions for our workers, ensures consistent high quality of products and maximises our efficiency. We are ready to respond to increasingly complex and global needs.

Automated Manufacturing

Green Factory

At Imex we are always looking to reduce our emissions, energy usage and carbon footprint, doing our bit to help preserve the environment.

We fulfil our commitment to creating a cleaner world by utilizing green technology such as wastewater treatment, flue-dust collecting systems, solar panels and more.

Once our new and improved factory is complete, we expect the following eco and energy saving benefits:

- Energy consumption will be 291kgce/t, lower than the industry benchmark of 300kgce/t

- Solar panels installed to save electricity.

- Carbon dioxide emissions reduced by 7,370 tonnes a year.

- $3.2 million invested to build two desulfurization systems to reduce sulphur dioxide and nitrogen oxide emissions.

- Our 2.1MW coal fired boilers were replaced with high efficiency gas fired boilers, reducing our coal use by 1,100 tonnes.

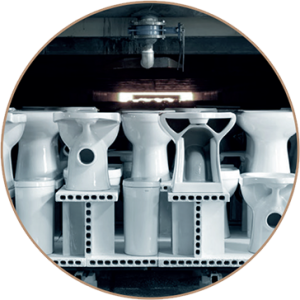

- New energy saving kilns not only help us to keep our green promises, but can also lower the cost of each kg of ceramics by 8% compared with traditional kilns.

Save Money, Save Water, Save The Planet

Our ‘Eco flush’ setting uses just 2.6/4 litres of water, which helps you reduce your water consumption

without compromising the effectiveness of the flush.

This not only saves you money but also uses less of the environments precious resource.

We are also proud to have achieved the following ISO certificates

Imex Design

Simplifying complexity and living freely is the basis of the Imex philosophy.

Based on the concept of “harmony between people and their environment,” Imex emphasises minimalist, durable, and practical designs.

Imex are constantly evolving with our attention to technological innovations.

It integrates the understated and simple aesthetic principles of the German and European schools with the craftsmanship of the East, excelling in creating comfortable and natural minimalist home products with concise design language.

Inspired by real-life situations, we create functionality that people really need.

Quality assured from fabrication to fitting

Our manufacturing process

Imex’s factory has passed certification in ISO9001, ISO14001 & ISO18001, ensuring the highest standards of product manufacturing are maintained

for optimal performance and ease of installation. As part of our commitment to quality, Imex carries out an 8-step inspection process on 100% of our product, as seen below:

1. Raw material

Physical & chemical testing against factory control standard.

2. Casting

Fully automated robotic casting for perfect results.

3. First inspection

Checking the product dimensions & physical appearance.

4. Glazing

Robot applied for even and complete coverage, flow rate, drying rate & density.

5. Firing

Efficient, energy saving kilns to help us keep our green promises.

6. Final inspection

100% Quality control, checking for air leakage & flush function testing.

7. Packing

Smart 5G connected warehouse and AGV racking system.

8. Shipping

Safe and efficient container loading for worldwide delivery.

Install with confidence

Full suite

Imex has a range of sanitaryware to suit all your needs. Whether it’s comfort height, short projection, wall hung, close coupled, rimless, or smart pans, we have it.

We also have ranges of baths (both freestanding and built in), furniture and taps allowing you to fully customise and turn your bathroom into your personal living space.

In addition, Imex have seat fixings and push buttons in chrome, matt black and brushed brass to match our brassware, wastes and bath shower screens, so we are a one-stop shop for all your needs.

Engineering

Where other manufacturers have been unable to, Imex have utilised high-pressure moulding to cast complex structures like our wall hung pans as a single piece, ensuring a seamless, robust product with minimal risk of air or water leakage.

Compliance

Our sanitaryware fittings are compliant with UK water regulations relating to fluid category 5 requirements.

Our fill valves feature non-return valves and an air gap greater than the requirement to eliminate any backflow of “blue water”.

Sanitaryware is CE certified, and our cistern fittings are either WRAS approved or in process of certification.